When You Can't Play With Wood, Play With Your Food!

If you are a passionate amateur woodworker like me, you may find yourself wanting to build your skills while unable to be in the shop. I've devised a quick solution for practicing your sense of design. It requires only some cheap items you probably have in your home already.

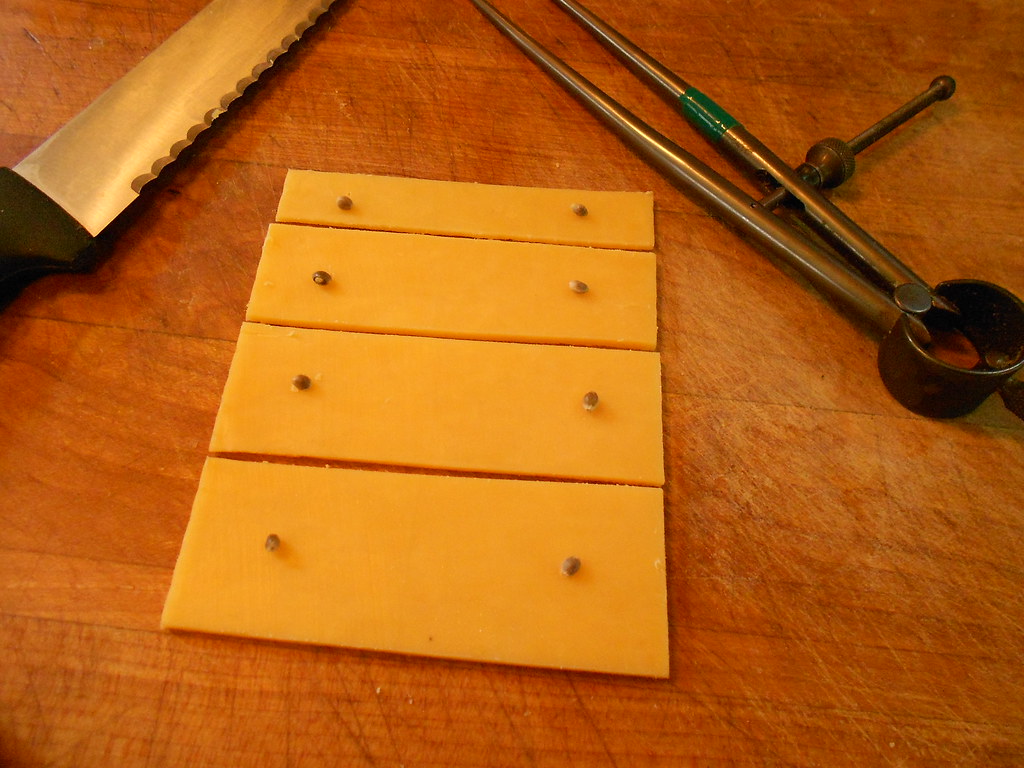

You'll need a workbench (a small cuttingboard), a simple saw of some sort (serrated, pocket, or even a butter knife), and a pair of clean dividers. You will also need some sheet materials readily available in all areas.

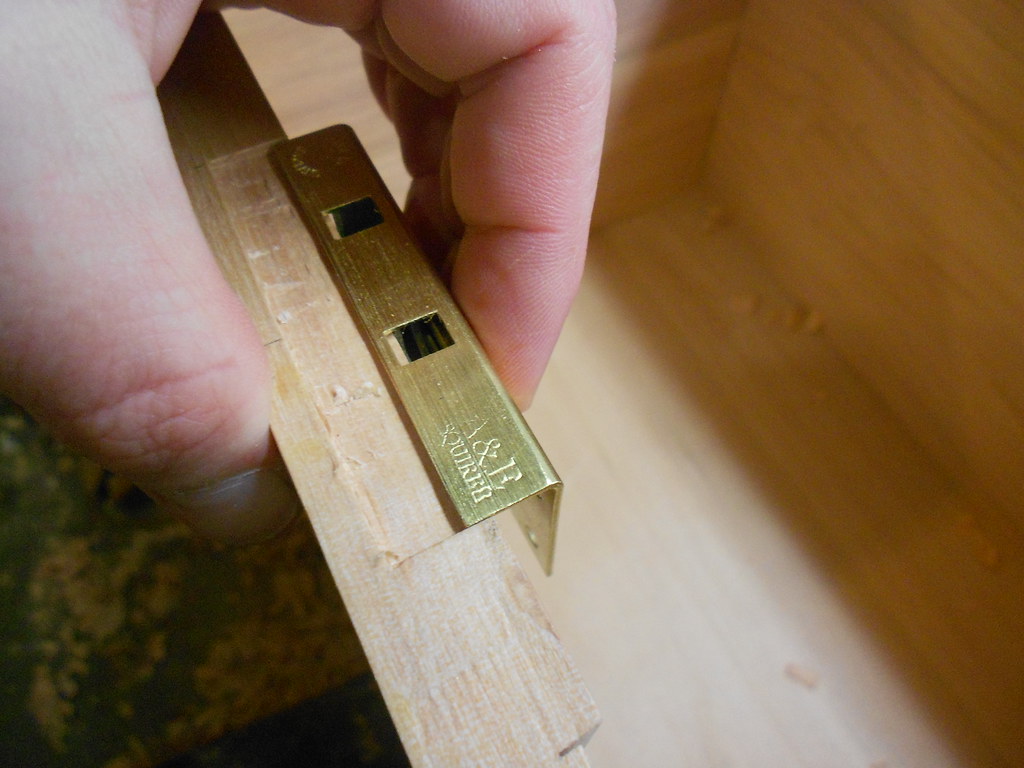

As far as the sheet goods go, as with lumber I always suggest seeking something local. Avoid dense exotics which can lead to tearout, such as crumbly stuff from the Parma region of Italy. You also want to avoid materials that are too soft such as those from France. Definitely avoid man-made aerosol products, with unknown effects on the environment and your own health. You may also consider "kiln-dried" materials, sold in "loaves" pre-sliced like veneer. These will most likely need to be squared before use though. Pay attention to grain, I prefer "8-grain".

Ready? Place a single sheet onto your bench, and use your knife to cut it perfectly in half. One side will undoubtedly be a little larger than the other. Both pieces may now be moved into the scrap bin or saved for a later project. Repeat if needed until you are confident spotting 1:2 by eye.

Now an exploration of classic proportions: For this you will need two identical square sheets. Cut one in half, as above, and place one of the half-pieces next to the other, forming a "square and a half", or 2:3 ratio. This is a classic shape for a table top or dresser. Study this form, devouring its essence and integrating it into yourself. Another challenge: With a new piece, attempt the same exercise as the first one but cut a 2:3 rectangle. Verify your work by setting your dividers so that it will take 2 steps to traverse one edge, and it should then take 3 steps on the adjacent edge. Try 1:5 and any other whole-number ratio you would like.

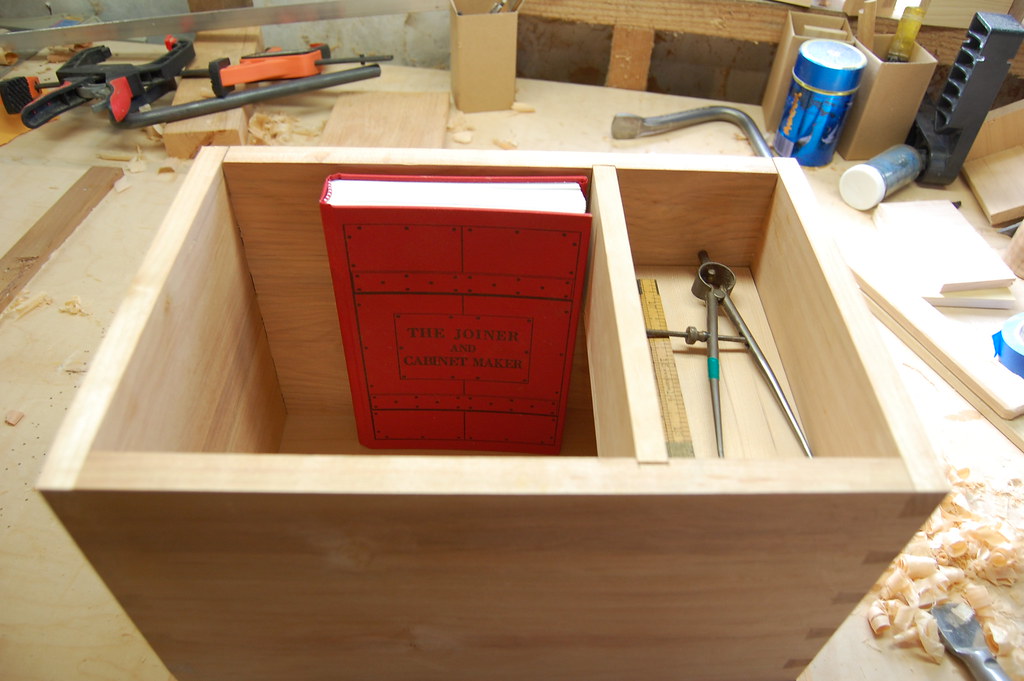

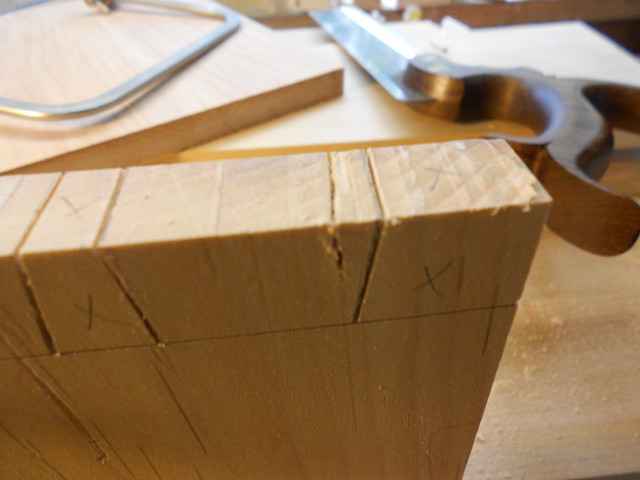

With your new eye for proportion and handtool skills sharpened, its time to design a masterpiece. Again create a 2:3 rectangle, oriented vertically. Set the dividers so that it takes 2 steps to get across the long (tall) edge, and put a small prick on the edge of both sides at the first step. Connect the dots with your knife, and you will have 1/2 of the slice cut free at the bottom. Repeat this on the top (larger) slice, again, resetting the dividers to 1/2 each time. Repeat once more, and you will have 4 different, and diminishing, sizes leaving you with a scale model of a chest of drawers, each harmoniously related to the other. Locate the pulls by stepping in 1/5th from either side on each drawer. Consider contrasting color and flavor, such as cheddar/roasted pepper. Continue to experiment, if you have the stomach, by laminating materials for all kinds of wonderful results. Repeat often with various ratios (1:3, 5:7, 3:8) to hone your eye for proportion.

A passionate woodworker is always hungry for practice in developing design skills, and so I do hope that this has given you a little food for thought.