Thursday, April 12, 2012

[oops] Confessions of an Inept Apprentice

The day started well and productive. I stopped for a coffee, a rare treat, and drove up 101 with its alternating sand and rock cliff coastline to get a few bales of straw for my chickens. The ocean air smelled great, and the occasional rain sprinkles seemed cleansing rather than ominously relentless as they can this time of year. It was a good day. After cleaning the chicken coop and spreading the fresh straw for them, it was time to hit the shop.

An eclectic mix ranging from flamenco guitar to bluegrass to punk was playing. The stacatto spring rain was breaking into royal blue skies. The shop door was open, and the dogs were laying on the stoop. A perfect day.

In the last session, I had carefully marked baselines and dovetails on all 4 boards for the next school box. I made sure to carefully label each board on either end, so that I would know which end to connect to which. I did this last time, too, but somehow became confused towards the end (did I plane off a letter? Not sure, but thankfully I recovered and it went together well.)

With nothing to do but cut to the pre-marked lines, I really concentrated on my saw technique. Better than usual! Maybe I am starting to figure this out? I remember the song "Los Angeles" by X playing, reminding me of my time spent in Southern California. I was in that timeless mindstate, where I feel most great art happens. Nothing is forced; its not that effort is not involved, but it doesn't feel like a drain. The saw was following the line, an extension of my will, and despite entering a type of revery, I was alert enough to stop cutting precisely as the baseline was reached. Rotate the board, do the other side. I was really feeling pleased with how well the cuts were going, looking forward to test-fitting the dovetails, wondering if they would be my best yet. Has it just been a matter of relaxing all along? Is this what competent woodworking feels like?

I was able to check myself here, knowing that pride is always a source of problems, and is one of my personal list of sins. I slowed down, made sure I was actually cutting as sweetly as it seemed. All looked well, but I would take no chances. I redoubled effort and attention, focussing more on the sound of the saw than on the hypnotic drone of Spacemen 3's "Mary Anne". All was still well, and I was re-pleased with my successes in sawing these precise joints.

Transferring the shape of the tails to the pinboard is always my most tense moment in dovetailing. Its kindof a one-shot deal... the knife needs to mark quickly and confidently-- if you do a 2nd stroke you will never know which is the more correct one--, and the board cannot move at all during the series of strikes (about 10, depending on how many tails are present). I try not to get too tense, but at the same time try to muster all available energy to maintain focus and perform as intentionally as possible. It seemed to go well.

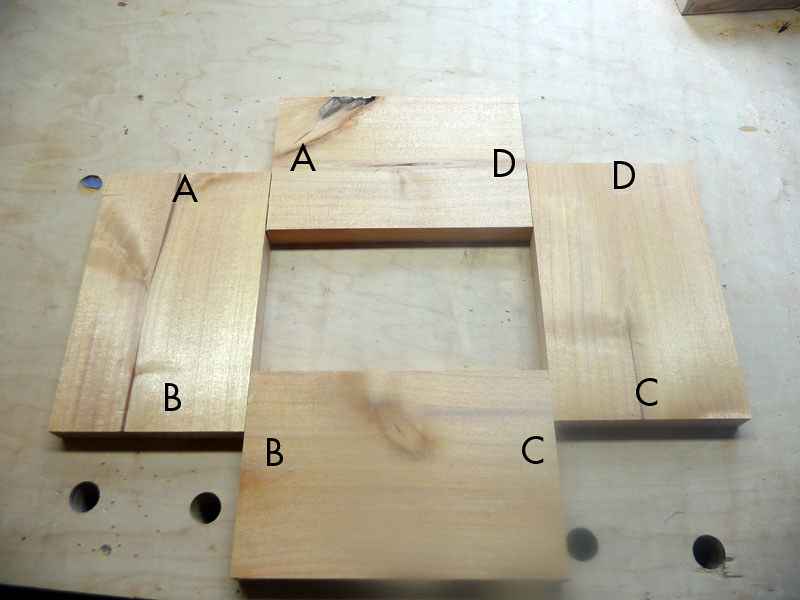

Since the shape of the pin depends upon the shape of the tail as it was cut, each pinboard has a "parent" tail board. The tails are cut as close to the line as possible, but it doesn't really matter if this is the case. What matters is that the pins match the tails exactly. If there is some variance in the shapes of the tails, the pins just have to be tweaked similarly to match. This is why the pins are marked from the tails (as cut) instead of from a similar layout process using dividers. This diagram shows the relationship between the boards:

I probably should have used lowercase letters to show that the 2nd letter of each set is dependent upon the "parent" but you get the idea.

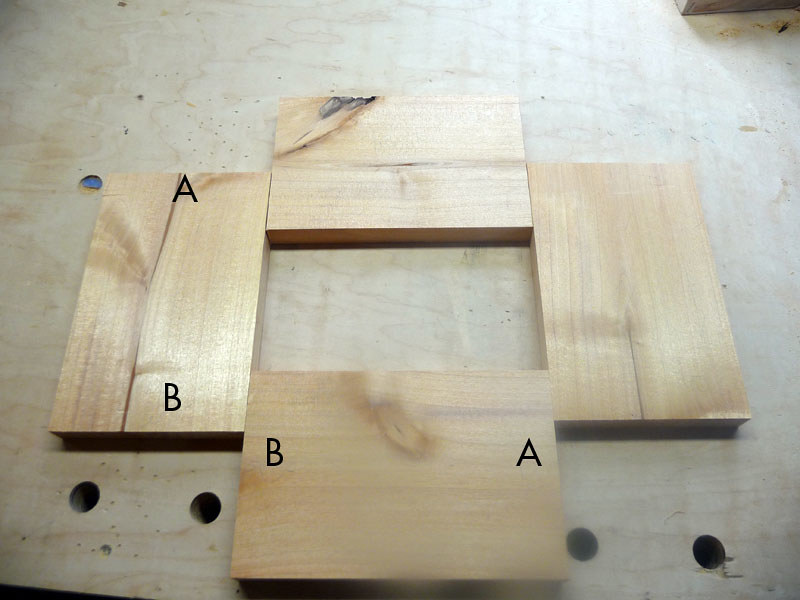

It was only after working halfway through the 2nd set of pins that that I realized I had actually done this:

Then 2nd set of pins, already marked and 2/3rds of the way cut, SHOULD have been transferred from the C tails... but I somehow used the other end of board I had already cut from instead of fetching the other.

If you are having trouble following along, it means that I marked the joints as if one board would be looped around in a U-shape, forming a D-shaped construction. No good.

In a perfect world, all of the tails would be marked using the same process, and no errors would be made, and all of the joints would be interchangeable. In this world, though, and especially when I am in command, this is not how it works. "A" is quite different from "B".

My options were few and far between. A negative spiral of panic was the most likely outcome. I did not have a spare pinboard to use (I had not milled any more lumber to the precise thickness of the box, and was not looking forward to that as part of the solution here). I could either continue with my chopping out of the joints, and pray to any number of deities that one or more would be interchangeable, or I could start over with a new board somehow.

I ended up ritualistically harvesting some alder trees and burning them in an ornate pyre-- just kidding. I just took a deep breath and rolled with it. Amazingly, I was able to pull out of this nose-dive at the last second, and it turned out that "A" and "D" (or something, I even confuse myself when the rules dynamically change like this) were close enough. Well, they were after some surgery. I did not take photos of the fit, I was too busy covering my rump. Suffice it to say that a couple deft paring strokes with a chisel eased the wrong pattern into the right one, and a 3/4 hammered-home test fit indicated this should work out ok.

Lesson learned.

Really, though, what is the lesson? This is not the kind of thing I want to do again, so it is important to integrate this fully. It boils down to relying upon myself (as the "marker"), and then faithfully carrying out those marking instructions (as the "maker"). In this case, my marking was to blame. I dutifully wrote "A" and "B" correctly, but something happened with my pinboard labeling. Was I tired? Hurried? Not sure, but I really do not want it to happen again. "Measure twice, cut once" works ok for saw cuts, but I need something like "Mark once, check twice, and then sign your marks with a complicated symbol indicating you actually thought about your mark 3 times".

My mantra in these times is "This is how I learn!".

Subscribe to:

Post Comments (Atom)

No worries. I have, on numerous occasions, reviewed my math at the drawing stage and at each such review, be it # 1 or # 5, have agreed that 2+2=5. Using the wrong end of a board from which to mark is but a minor example of such brain spasms that happen to all of us.

ReplyDeleteGood Post

Thanks for following the trials and trevails, Mentis!

ReplyDeleteDon't make us start calling you Sam. Seriously, though, I've done this more than once. I typically number all my joints, but that doesn't stop me from still screwing it up. Usually this happens when everything is getting glued up, at which point all hell breaks loose. I like how Peter Follansbee uses small little tick marks with different gouges to match his joints. Keep up the good work. You're almost ready for the dresser.

ReplyDelete-Eric

Cabinetmaker's triangles are your friend! It's much easier and ultimately more intuitive than matching letters or numbers at joints. I used the lettering method for years until Chris Schwarz cured me of that habit at his toolchest class in NC...

ReplyDeleteedhrekso - I actually tried that initially but it is hard to find a spot where the mark won't be cut away... so I have started to just re-mark the letter once the sockets are cut. I'd love to see an example of using the triangle on dovetailed boards

ReplyDeleteI wish I had a good picture, but I'm in a hotel room away from home for the next few weeks. Chris taught us to use the mark on the top middle edge of each board. Since you most likely won't plane the top edge until after your carcass is put together (assuming you reference everything from the bottom, you won't likely remove it accidentally. On a box like the one you're making, 2 triangles is all you need to indicate top from bottom, front from back, and left from right. I'll try and sketch something out on a piece of paper and email you a pic.

ReplyDeleteI have done exactly the same thing...you made me laugh.

ReplyDelete