-- The Joiner and Cabinetmaker, 1839

Clinching is spelled clenching in the book, but I prefer "clinch" as it has a more appropriately archaic feel. At any rate, nails were clinched. Its much harder than it sounds, or at least I find it to be.

Like Thomas, I started out using a tiny anvil underneath the box. However, my little anvil is terribly rusty, no matter how much I clean it. It leaves nasty discoloration on the wood, so I aborted that. I took a tip from Chris Schwarz, using the wing of my table saw as a giant backing plate. Then, I used a hammer to coax the nail tips downward (also not as easy as it sounds):

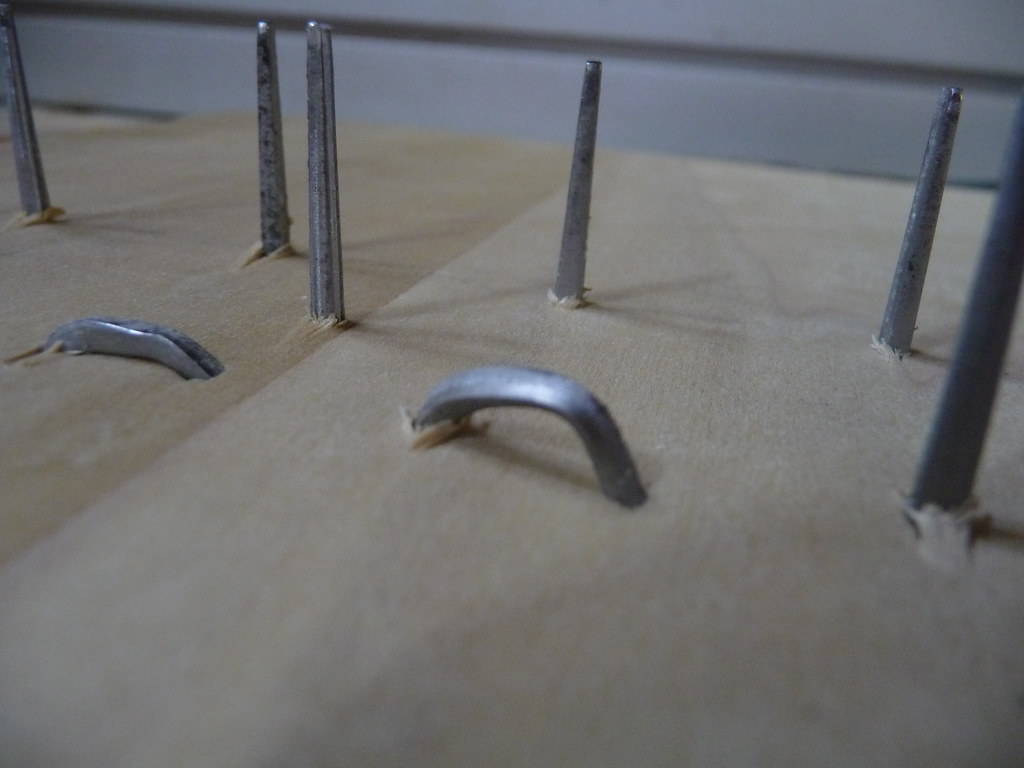

A few more taps, and it bends a little more, making contact with the wood:

More blows are delivered until its sunk all the way in:

And then repeat the whole process for the other 63 nails:

I probably should have used thinner nails, or brads, but had only 4d ("four penny") fine-finish nails on hand, the same ones used to attach the sides and bottom to the box. Thomas uses 4d nails as well, but no mention is made to their thickness or if they are nails or brads. Studying Schwarz's images does not provide further clues, but his demonstration on the Woodwright's Shop makes it look like he is using brads and not finish nails. I suspect that makes this process much easier.

It is very difficult to sink the flattened, clinched nail flush with the wood. The hump which remains is near impossible to drive flat into the wood, although surely this is easier in a softer wood. You can see in the above photo not only the humps which remain, but the hammer-face-shaped "French marks" which result from trying to pound them flatter.

The result is an extremely strong joint; 8 or 10 nails would likely be more than enough to hold the cross-strengtheners onto the box, but remaining faithful to the illustration, I overbuilt the box just as Thomas did.

I worry somewhat about the nails on the bottom of the box and what they could do to delicate conents, such as Mr, Green's fancy books. This could be easily remedied by placing a panel over the nails, or even a piece of cardboard.

My impression now is that clinching is indeed a very effective mechanical joining technique, but it is not attractive and is not pleasant to the touch. I would only reserve this for the crudest construction projects, or when strength is much more important than aesthetics. In the images above, I tried using all of my might to keep the nails as parallel and straight as possible while clinching. I am sure that skill comes with time, but I still feel the end result is rather nasty looking, and it took a very long time to do it.

First page I've looked at here and I love this - a while ago I watched Mr. Underhill demonstrate this on a video I found online (actually I think a guest did the work) and it was what finally got me thinking old ways make sense. They're generally much more thought out by people who did the tasks for a living, rather than people who make their living finding new things to convince us we need to buy. Sure, it isn't pretty in a "Look honey at the fantastic joinery I used to make your xmas with" way, but it has a real elegance in function. Getting a bit-o-wire to do more work than is reasonable to expect. Thank you.

ReplyDeleteThanks for stopping by, Fitzhugh. You did indeed see a guest on Woodwright's Shop clinching nails. It was Chris Schwarz, co-author of "the Joiner and Cabinet Maker" which is the inspiration for this blog.

ReplyDeleteYou can watch the video here:

http://www.pbs.org/woodwrightsshop/video/3000/3010.html

Can someone please tell me, in framing, why you would clinch a nail? We recently dug up several clinched cut nails in the yard. My kids are asking why they are all bent. I knew they were clinched, but was at a loss as to why.

ReplyDeleteThanks,

Jeff